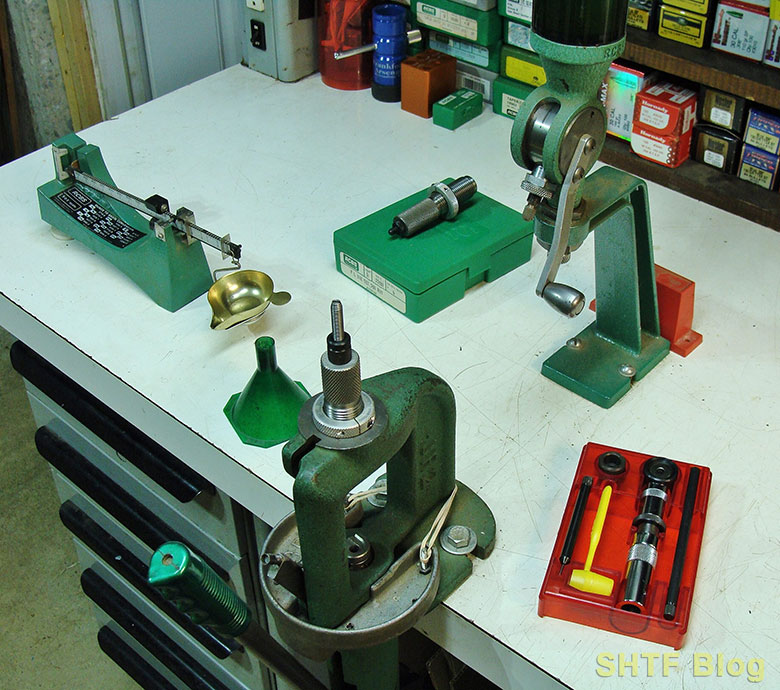

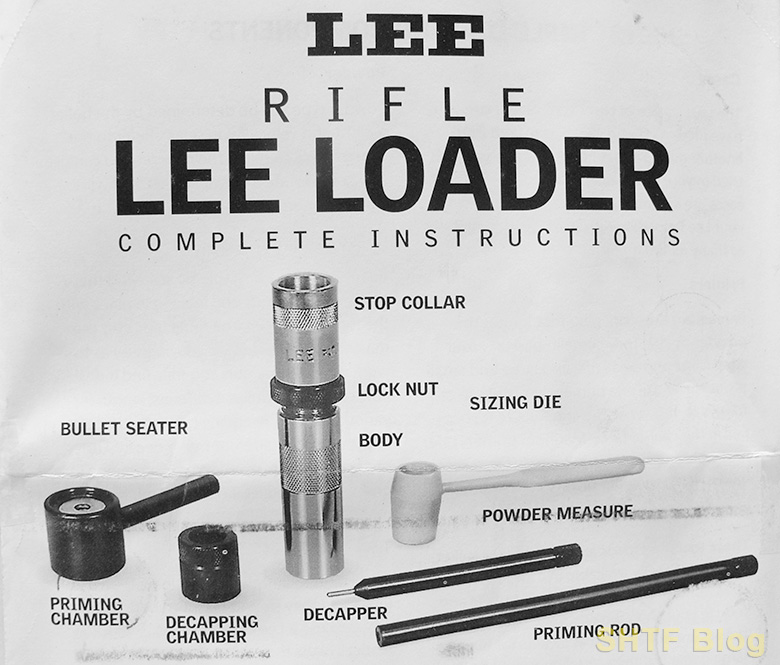

Amongst a latest treasure trove of used reloading gear offered by a good friend, I found an previous however acquainted merchandise, a Lee Precision Basic Lee Loader. These small kits have been bought for greater than 60 years. Easy, inexpensive, and transportable, they will restore a provide of fired brass instances to totally purposeful cartridges just about anyplace, from a tailgate to a distant cabin. My reloading profession started with a Lee equipment years in the past in a much less unique location – my bed room, on the ripe previous age of fourteen.

And, as an alternative of metallic cartridges, I used to be reloading shotgun shells. The reloading bench was the highest of my dresser, and the whole “press” was saved in a drawer. The method was much more labor-intensive than my present progressive-press loading system, however the ultimate product – a 2 ¾” 12 Gauge goal load – was each bit pretty much as good if not higher.

When you’re simply getting began with reloading I’d additionally counsel following this hyperlink to learn extra on the topic.

Sadly, the shotgun model is not cataloged. Nonetheless, Lee nonetheless lists their kits for a lot of rifle and handgun calibers. The worth, at beneath $50, is true.

Store on your caliber Basic Lee Loader at Optics Planet.

Basic Lee Loader Take a look at-Run

For the reason that gifted .30/06 Basic Lee was in pristine situation, I made a decision to present it a attempt. I had a great assortment of elements, however one doable stumbling block was powder appropriate for the equipment’s scoop measure.

Parts

Of the various powders with totally different burn-rates and densities, just some will likely be protected for a given caliber and its projectiles. Past that, specified expenses have to be used to take care of protected pressure-parameters. My longstanding ’06 looking load, fueled by IMR 4350, is charged by weight (in grains) from a fastidiously adjusted powder measure. However the equipment makes use of a fixed-volume powder scoop.

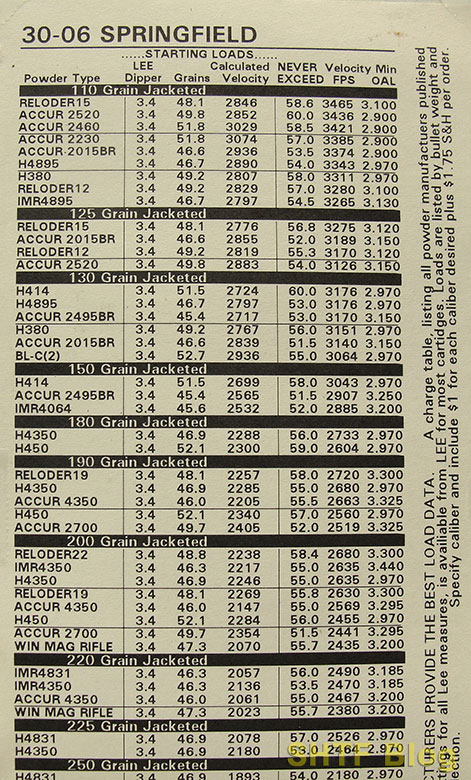

Lee gives a chart that exhibits appropriate powders for standard bullet weights, however IMR 4350 wasn’t listed. Fortunately, of the three propellants proven for 150-grain bullets, my on-hand cannister of IMR 4064 did seem. From there I used to be in enterprise by way of a stash of CCI 200 Giant Rifle Primers, Hornady 150-grain Interlock Spire-points and a group of cartridge instances.

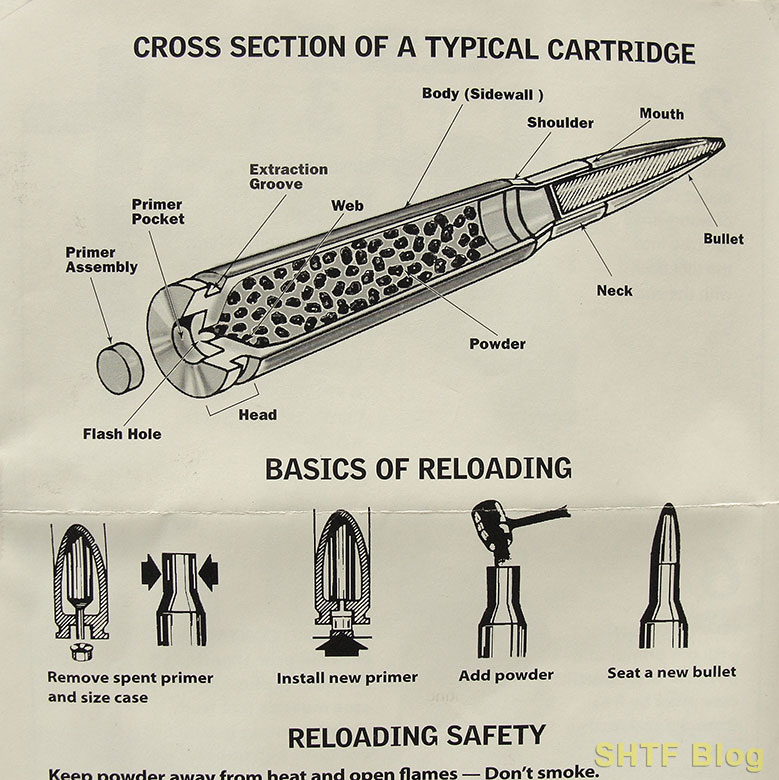

The place to begin was a batch of fresh instances with equivalent headstamps. A field of as soon as fired ’06 brass had that coated however posed a priority, having been fired in a number of rifles. The Lee equipment consists of clear and simple to comply with instructions, beginning with a diagram of the steps. Not talked about there (however coated afterward) is the important resizing course of.

Case Resizing

When you’ve got a provide of fresh Boxer-primed (normal U.S.) instances, fired in your gun, the Lee resizing die ought to work tremendous. Brass is an ideal materials for a metallic cartridge due to its elasticity. The identical stress that expels the bullet will broaden the case to seal it towards the chamber’s partitions. Because the bullet exits and stress subsides, the brass case will contract for straightforward extraction – from that exact chamber.

Nonetheless, due to tolerances, it may very well be too giant to suit others. Because of this, most of us squeeze our fired instances again to manufacturing unit specs by way of full-length resizing dies and high-leverage presses. The method requires lubricant and appreciable pressure – a problem for a easy hand device. Resizing solely the ahead part (bullet-gripping neck) requires lots much less – the rationale why Lee kits are designed to “neck-size” bottle-necked cartridges.

Case lube wasn’t talked about within the instructions however, taking part in it protected, I did apply a swipe of Imperial Sizing Die Wax to the primary ’06 case. Resizing was a lot simpler than anticipated so I skipped it for the remainder.

The Lee Loader Reloading Course of

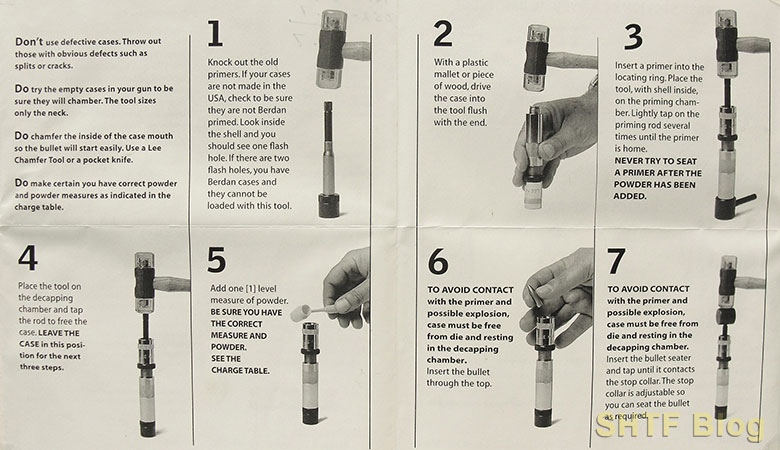

I deliberate on photographing every of the seven steps however, because it turned out, Lee already had the method coated by way of clear images.

Step 1: Knock out the previous primers.

Step 2: Drive the case into the device flush with the tip.

Step 3: Insert a primer into the finding ring

Step 4: Use the decapping chamber and faucet the rod to free the case.

Step 5: Add your powder.

Step 6: Insert the bullet by way of the highest.

Step 7: Insert the bullet sealer and faucet into place.

Step #5 Word: Earlier than charging the primary primed case, I stuffed the equipment’s 3.4 cc dipper with a leveled cost of IMR 4064. My powder scale indicated a weight of 46.5 grains – greater than the 45.6 grs. listed for the dipper, however nonetheless beneath the info proven in my Hornady guide. A number of extra observe scoops produced related weights, plus or minus a couple of tenths of a grain – deemed shut sufficient.

Step # 7 Word: Previous to seating the primary bullet, I unscrewed the die’s locknut and backed out the cease collar. Then, by way of trial and error (utilizing vernier calipers), I step by step elevated the seating depth to coincide with my current handload. The nut was locked when “cartridge general size” was 3.230”, equivalent to the C.O.L. proven in my now-dated Hornady Handbook (third Version).

We Have A Cartridge!

The primary .30/06 Lee handload regarded each bit pretty much as good as my press-produced cartridges. It additionally chambered with out issue in a Remington Mannequin 700 (fastidiously loaded on my outside vary). Similar for the subsequent two, at which level I halted manufacturing to arrange a taking pictures take a look at.

Take a look at Hearth

Figuring the Lee handload would shoot near my established looking load, I positioned a goal at 100 yards, arrange the chronograph, and fired one shot off sandbag relaxation. It hit virtually dead-center and extracted with out points. As anticipated although, velocity was solely 2559 fps (15 toes off the muzzle), a tad sooner than Lee’s 2532 fps declare, in all probability on account of my barely heavier cost and/or the M-700’s 24” barrel.

Issues have been wanting promising however the subsequent two photographs clocked 2469 and 2415 fps – one heck of a velocity unfold! The 144-fps excessive little question defined a vertically strung 2 ½” group – not the norm for this rifle.

The issue coming to thoughts was my dipper approach, known as good after only a few observe dips. To seek out out, I in contrast a couple of extra dipper expenses to the size. Outcomes have been inconsistent so I used the dipper and scale to assemble three extra cartridges with weighed 46.5-grain expenses.

Massive enchancment; 2478, 2478, and 2481 fps (an excessive unfold of solely 9 fps)! The second sequence coincided with the 2 slower photographs from the primary, to kind a 5-shot a 1 ¾” group – not stellar, however nonetheless helpful. Velocity was solely round 100 fps sooner than a .30/30, nevertheless the load is topic to enchancment by way of extra throttle (see beneath).

Assuming a Lee equipment is used with constant brass and powder expenses, there’s actually no purpose why it shouldn’t produce correct cartridges. Truly, many choosy handloaders neck-size to attain exact chamber alignment, which frequently interprets to tighter teams.

Helpful Extras

Bottle-necked cartridge instances are inclined to stretch lengthwise throughout a number of firing cycles and, though much less of a problem with neck-sized brass, most case size ought to by no means be exceeded! The neck wants some clearance to launch the bullet. If pinched towards the chamber, harmful pressures might develop.

Case Preparation

Earlier than making an attempt to reload the above Remington .30/06 instances, I measured their lengths with a dial caliper. Having solely been fired as soon as, they hovered round 2.488”, safely beneath 2.494” max. If not, their necks would’ve required a trim and, among the many varied gadgets bought for this objective, the only is Lee’s caliber-specific case-pilot & cutter system.

Case trimmer, Gauge/Holder: Features a caliber-specific shell holder and pilot to manage size.

Case trimmer, Cutter & Lock Stud: Features a common mount for the required shell holder, and common case reducing device.

Case Chamfer Instrument: Chamfers and deburrs the inside and outside of case necks (to ease bullet seating). May also be used to deburr the crimped primer pockets widespread to navy brass.

Primer Pocket Cleaner: Removes fouling from each small and enormous primer pockets for constant seating of latest primers.

Powder Cost

The plain draw back to the above handload was its low velocity – anticipated since its 46.5-grain cost of IMR 4064 was a full grain beneath Hornady’s beginning load. Hornady’s knowledge spanned 47.5/2700 fps to 52.6/3000 fps from a 22” barrel.

My pet IMR 4350 looking load does 2850 fps. Lee’s chart exhibits a max of 288 fps, utilizing 52 grains of IMR 4064. And, to succeed in that stage, two easy speed-boost options can be found.

Powder Measuring Equipment: Spend money on a full set of dippers (15 in all from .3.0 – 4.3 CCs) with complete knowledge.

Lee Security Powder Scale: Extremely worthwhile! Offers higher load flexibility (see beneath). Additionally, one of the simplest ways to verify protected and correct powder expenses.

Different Good Investments

Phrase-of-mouth load recipes are dangerous and Web sources are sometimes no higher. Lee’s chart is the a lot safer place to begin, however a presently dated reloading guide remains to be value each cent. One instance of a number of: The Hornady Handbook (now in its 11th version), is offered as printed and digital variations.

Like others, it incorporates helpful reloading info and covers a variety of masses – with additional worth for cross reference functions.

A caliper (dial or digital) will present the measurements wanted to regulate essential cartridge dimensions. A helpful final step: Label every field of handloads with the entire pertinent knowledge to incorporate the elements, general size, and the meeting date.

Final Ideas

Given these unsure instances, ongoing shortage of ammunition and its escalating value, a stash of brass and a cheap reloading system might make sense. The Basic Lee Loader is presently obtainable in fifteen calibers, together with six standard handgun picks.

For initiatives like a 500-round batch of .223s, I’ll follow the press-equipped reloading bench, thanks. However the gear and elements represent a big pile of “stuff”, not very conducive to mobility. For decrease quantity manufacturing typical of cartridges just like the ‘06 (and lots of others), a Basic Lee Loader might nicely be the right on-the-move different.

Granted, elements aren’t low-cost, however they are often procured piecemeal by way of native or shipped sources. This stuff, and the gear, additionally seem at gun exhibits and even storage gross sales, for substantial financial savings. The most costly part is usually the cartridge case. However, because of Lee’s extra mild sizing course of, they need to be good for a minimum of a number of firings – if not a heck of much more!