Rob Ziarnick, founder and proprietor of Gunfighter Design, has been designing and making blades for over 5 years and determined it was time to check the boundaries of his product. He reached out and requested if I may take a fantastically crafted, handmade knife and, “put it via an insane quantity of abuse and write about it”. When Rob supplied to ship me a pattern of his POPS (Skilled Outdoorsman Precision Skinner) MK2 and submit it to some gnarly testing, how may I refuse?

Gunfighter Design has an attention-grabbing story that began again in 2018. With the objective of creating an excellent knife, the unique design was a lounge collaboration with Rob’s buddy and colleague Michael Baccellierli (aka Buck). Each Buck and Rob hung out addressing the shortcomings they encountered with knives previously. Each have been Marines and Snipers who broke knives whereas on fight deployments. Energy, ergonomics, performance, and usefulness in multiple process result in their prototype design, the Ravens Head. The double thumb reduction or DTR was born, in addition to the concept to include a glass breaker. After making the primary Ravens Head in a small propane forge with a bit of 80CrV2, it despatched Rob on a journey of creating knives as a enterprise. Simply as he was getting began, he was struck by a drunk driver, and was uncertain if he may ever bladesmith once more. However Rob is as robust because the knives he makes, and was again within the bladesmithing saddle very quickly. Partnering with Eric Moser, a retired Inexperienced Beret Sniper, machinist, and somebody who additionally had expertise with knives breaking in fight, they started manufacturing with a brand new and improved design.

Subscribe At present and Save!

Movies of every kind of blade destruction assessments exist, however I didn’t wish to wreck a superbly good knife only for the sake of seeing it damaged. A minimum of not at first. I made a decision that I needed to push its limits in a useful sense, earlier than seeing what it’d truly take to bodily harm it past restore. Most knives are usually able to performing three primary capabilities, piercing, chopping and slicing. The POPS MK2 was going to be evaluated on its means to retain its edge and unique design specs, whereas performing these capabilities throughout testing.

The Blade

POPS MK2 is an absolute beast of a blade, not as a result of it is the longest fastened blade on the market, however due to its design and composition. Made out of CPM 3V, it is cast from powdered, excessive carbon metal with a excessive quantity of vanadium. Crucible Particle Metallurgy, designated by the CPM has a a lot finer grain sample, and a extra even dispersion of alloy components. 3V signifies that the metal has round 3 % vanadium, which is particularly used to extend hardness and edge retention. CPM 3V is specialised metal that’s usually utilized in industrial shear blades, or business forging punches, however Gunfighter Design is utilizing it within the type of a skinning knife!

Above: A number of supplies have been chosen to check the blades hardness, sharpness and sturdiness. These embrace seasoned maple batons, a brass rod, and a copper tube.

The blade itself is 3.5 inches, and eight inches over all, with a girthy width of 5mm. A useful glass breaker is floor into the tip of the butt, and titanium eyelets maintain G10 deal with slabs in place. For a hard and fast blade on the quick finish of the spectrum, it has sufficient mass to let weight and gravity do many of the slicing work. It is a thick, vast blade, and the bevel skirts the border between meat cleaver and hatchet. One of the crucial distinctive options is its Double Thumb Aid on the backbone of the blade. Inserting your thumb on the backbone when holding a knife is typically referred to as the “saber grip”, and it’s used to increase your attain. Including a reduction notch affords extra management, and the second reduction notch allows you to work the blade with extra dexterity in tight locations.

Primary Exams

Earlier than stepping into the intense efficiency assessments, I needed to determine a comparatively easy baseline of its slicing capabilities. Among the finest methods to do that is solely letting the sting slice via a bit of ordinary printer paper. The sting of the POPS does this simply sufficient, though the width of the blade slows down its momentum. That is completely high quality because the blade is made for breaking bone and slicing via ligaments and sinew. Because it’s a model new knife, there are not any chips or rolls alongside the sting. Now that I do know that it is sharp and can slice simply, it is time to take a look at its piercing and chopping efficiency.

Above: With the ability to easily slice a bit of printer paper is a simple approach to take a look at a blades’ sharpness.

For chopping, I’ve three gadgets of various densities: wooden, copper and brass. First up is a seasoned arduous maple baton. Summoning my interior Jay Nielson, I swing the POPS into the wooden with as a lot power as I can muster. The blade chews via the baton like a hungry beaver, leaving the sting completely intact. So as to add further power behind it, I exploit a second baton and hit the backbone of the blade to drive the sting into the wooden deeper. To take away it from the wooden, I pry the blade so far as I can forwards and backwards. The metal stays straight, and the sting stays true. Turning it on its level, I baton the blade tip-first into the wooden so far as I can go, prying it forwards and backwards to take away it. POPS stares again at me unphased.

Above: Seasoned sugar maple is a hardwood that can give an axe a run for its cash, however its only a stroll within the park for the POPS MK2.

Okay, nice, it could deal with wooden, nothing supernatural about that, so lets attempt it in opposition to some comfortable metals. POPS is batoned into copper pipe, after which right into a brass rod. The copper pipe is lower and bent, and the brass rod is lower via as effectively. Nonetheless the sting of the POPS stays in pristine situation. No rolls, no chipping. Possibly a number of the anodized end is blemished, however past that, it is like nothing ever occurred. I do a observe up slice take a look at on the paper and see a slight lower in sharpness. However after a couple of passes on an 800 and 1000 grit stone, and somewhat stroping, it is slicing higher than ever.

Above: Copper has a hardness between 45 and 50 on the Rockwell Hardness Scale (HRC).

At this level, I really feel the POPS MK2 has held as much as greater than would ever be requested of it, even in probably the most troublesome settings. It may be pried with out shedding its straightness. If it could lower via brass, it could absolutely lower via bone unphased. Clearly the warmth remedy–a knife making course of that impacts the standard of metal hardness–was completed expertly. The sting sharpened simply, and over all, I might rank this as a prime notch looking knife. Sadly for the POPS, I used to be requested to punish the blade, and wanted to crank issues up a notch to push it to its limits.

Above: Brass, a composite of zinc and copper, has a hardness of round 30 HRC.

The Punishment

I wish to preface this by stating, on the file, that I like handmade knives, and I cringe each time I see destruction testing taken to the acute. Somebody’s arduous work, ability and time goes into each blade, and to purposefully destroy one appears disrespectful to me. So simply know, that what I’m about to do might have been tougher on me than it was on the knife.

On a knife, the tip is likely one of the weakest, if not the weakest level. Any inconsistencies within the warmth remedy could cause the tip to bend or break. I already know the tip of the POPS can maintain as much as hardwood and comfortable steel, however what about chipping its means via ice? For this punishment, I’m not utilizing your regular, clear, run-of-the-mill ice. As an alternative I chip my means via 4 inches of stamp sand and gravel that is been frozen strong and compacted by a county snow plow over the course of a number of months. After a number of minutes of steady chipping, POPS survives! The tip didn’t break, bend or roll, and it didn’t lose a lot of its sharpness. The truth is, I might go as far as to say a gap may very well be augered for ice fishing utilizing this blade in case you have been in a pinch.

Above: Chipping via a concrete combination of ice and gravel proved to be a boring problem for the POPS MK2.

Punishment quantity two is a take a look at of its total integrity. Thus far I have been focusing primarily on the sting and its performance, and total it appears bullet proof. However what in regards to the deal with and the remainder of its building? To search out out what this factor is manufactured from, I place the knife flat on the gravel strewn ice pack, and soar in my truck. Every truck tire exerts roughly 1,400lbs of contact stress with the bottom, and since I am shifting, that stress is rolling alongside the width of the blade at completely different factors at completely different occasions. Any issues with the warmth remedy or deal with building will trigger a essential failure of the blades integrity. First I again over the POPS with the rear tire, then the entrance tire, then drive ahead and get it with the entrance, then once more with the rear tire. POPS has been pushed over 4 occasions. Then I repeat this course of 4 extra occasions for good measure for a complete of 20 occasions. At one level I turned nervous in regards to the blade going via the tread of my tires, however I threat all of it for the sake of science!

Above: The POPS MK2 awaits being run over, repeatedly, by a full dimension pickup truck.

Getting out of my truck, I stroll round to see what occurred to my beloved tanky POPS, and… it survives! Not solely did it survive, however it appears fully indestructible at this level. The backbone of the blade remains to be straight, the G10 deal with slabs haven’t come unfastened, and if there’s any harm in any respect, it is solely to the anodized end. Even the G10 seems unscathed after cleansing it up a bit.

At this level I am going through a little bit of a conundrum. I used to be requested to brutalize this factor, and apart from throwing it within the fires of Mount Doom, or dragon’s breath, I’m not precisely positive what else to do to check it. My thoughts wanders to taking the blade to the vary and throwing some lead at it, however lead is way softer than brass, regardless of how arduous you toss it at one thing. The truth is, given the speed, mass, and acceleration of your frequent 9mm, you’d solely be exerting about 1,600lbs of stress on the blade. Granted, at a lot sooner speeds, however nonetheless, that is only some extra kilos than truck tires. And we simply did that twenty occasions in a row. I wander via my storage on the lookout for inspiration, and discover it within the type of a 10lb sledge hammer. Imagine it or not, relying on how briskly and arduous the swing is, a metal sledge hammer can produce astronomical quantities of stress. We’re speaking within the double digit tons of stress.

Choosing up the sledge, and inserting the POPS down reverently on the compacted ice, I placed on some security glasses, and say some last phrases to at least one stubbornly sturdy knife. Aiming for the flat of the blade, I swing the sledgehammer overhead as arduous and quick as I can. Ice and gravel spray violently in all instructions. Wiping clear the particles from my security glasses to evaluate the harm, I discover, to my astonishment… POPS survives! Simply to make certain, I swing once more. POPS survives! And once more. POPS survives! It isn’t till the sixth swing of the sledge that POPS suffers a catastrophic failure.

Above: It took an insane quantity of punishment to lastly inflict sufficient harm to trigger the blade to interrupt.

Failure occurred at the place the deal with meets the ricasso of the blade, which is a standard place for a break to occur. Close to the break, there’s a titanium eyelet, and my greatest guess is that there was simply not sufficient metal in that location to soak up the ferocious affect of a number of sledgehammer blows. Aside from the break, the G10 appears somewhat roughed up however nothing main contemplating what it simply went via. The blade itself is unbent, and when pieced again collectively, makes a superbly straight line.

Conclusion

Iron is a magical factor within the palms of somebody who is aware of tips on how to manipulate it. Combine it with the appropriate components and it turns into an alloy metal that takes on otherworldly properties. Within the case of the POPS MK2, it’s a metal blade that might outlast humanity if taken care of correctly. Barring industrial slicing instruments, or temperatures that exceed 2,000 oF, Rob, Eric and Gunfighter Design has introduced a knife to market that you can rely on along with your life. Though the blade is now damaged, will probably be stored as a reminder of what dedication to high quality and a spotlight to element can obtain.

Associated Posts

Put together Now:

Disclosure: These hyperlinks are affiliate hyperlinks. Caribou Media Group earns a fee from qualifying purchases. Thanks!

Disclosure: These hyperlinks are affiliate hyperlinks. Caribou Media Group earns a fee from qualifying purchases. Thanks!

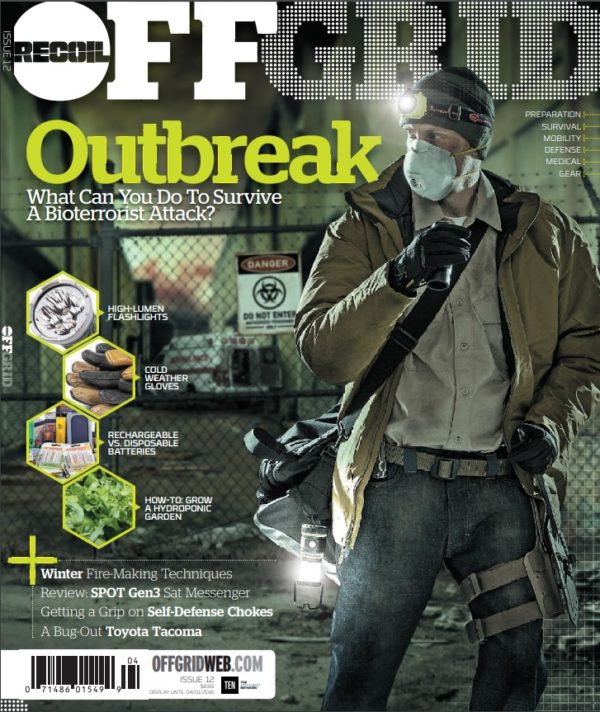

STAY SAFE: Obtain a Free copy of the OFFGRID Outbreak Situation

STAY SAFE: Obtain a Free copy of the OFFGRID Outbreak Situation

In situation 12, Offgrid Journal took a tough take a look at what you need to be conscious of within the occasion of a viral outbreak. We’re now providing a free digital copy of the OffGrid Outbreak situation once you subscribe to the OffGrid e mail publication. Join and get your free digital copy